What is a Custom RFID Antenna Design?

Custom antenna design involves the tailored creation of antennas specifically optimized for radio frequency identification (RFID) systems. These antennas play a crucial role in the performance of RFID technology, influencing factors such as read range, accuracy, and reliability. Through custom design, factors such as frequency, polarization, shape, size, and material composition can be meticulously adjusted to suite the unique requirements of the RFID application, whether it's for inventory management, access control, or asset tracking. By crafting antennas tailored to the specific environment and usage scenario, custom RFID antenna design enhances the efficiency and effectiveness of RFID systems, ultimately contributing to smoother operations and improved overall performance.

Why Would Someone Need a Custom RFID Antenna Design?

There are several reasons why someone might require a custom RFID antenna design:

- Specific Application Requirements - standard off-the-shelf antennas may not meet the unique requirements of a particular RFID application. Custom RFID antennas can be designed to optimize performance in specific environments or scenarios, such as harsh industrial conditions, densely packed inventory, or long-range tracking.

- Space Limitations - in some cases, the available space for installing an RFID system may be limited or irregularly shaped. Custom antennas can be designed to fit within these constraints while still providing optimal performance.

- Read Range Optimization - depending on the application, users may need to maximize or minimize the read range of the RFID system. Custom designs allow for precise tuning to achieve the desired read range, whether it's for long-distance asset tracking or short-range access control.

- Interference Mitigation - in environments with high levels of electromagnetic interference (EMI), standard antennas may suffer from reduced performance or reliability. Custom antenna designs can incorporate features to mitigate interference and improve signal integrity.

- Integration with Existing Infrastructure - for retrofitting RFID technology into existing infrastructure or equipment, custom RFID antennas can be designed to seamlessly integrate with the layout and constraints of the environment, ensuring compatibility and ease of installation.

- Unique Form Factors - some applications may require RFID antennas to be integrated into products or devices with unique form factors. Custom RFID antenna designs can accommodate these requirements while maintaining performance and functionality.

Overall, custom RFID antenna design offers flexibility, performance optimization, and tailored solutions to meet the specific needs of diverse RFID applications.

What are the considerations for RFID antenna design?

Designing RFID antennas requires careful consideration of various factors to ensure optimal performance and functionality. These considerations include selecting the appropriate frequency range to match the RFID system, choosing the right antenna type based on size constraints and application requirements, optimizing antenna size and form factor for space-constrained environments, determining the desired gain for achieving the required read range, selecting the appropriate polarization to minimize signal losses, designing the radiation pattern to cover the desired read zone effectively, ensuring proper impedance matching for maximizing power transfer, considering environmental factors such as temperature and electromagnetic interference, and accounting for manufacturing considerations to ensure cost-effective production.

How are RFID antennas made?

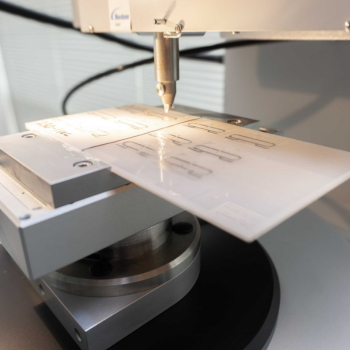

RFID antennas are typically made using a combination of materials and manufacturing techniques tailored to the specific requirements of the RFID application. The process generally involves several key steps. First, the antenna design is developed based on factors such as frequency range, size constraints, and desired performance characteristics. Once the design is finalized, the antenna is typically fabricated using methods such as printing, etching, or deposition onto a substrate material, which can be flexible or rigid depending on the application. After fabrication, the antennas may undergo additional processes such as curing, coating or lamination to enhance durability, environmental resistance, and electrical performance.

What is the difference between an RFID antenna and an RFID reader?

The fundamental difference between an RFID antenna and an RFID reader lies in their respective roles within an RFID system. An RFID antenna serves as the interface between the RFID tag and the RFID reader. It emits radio waves to power the RFID tag and receives the response signals transmitted by the tag.

On the other hand, an RFID reader, also known as an RFID interrogator, is the device responsible for transmitting signals to the RFID antenna, receiving and decoding the response signals from the tags, and processing the data obtained. While the RFID antenna facilitates wireless communication with RFID tags, the RFID reader acts as the control unit responsible for managing and processing the data exchanged between the tags and the reader system.

What is the frequency range of an RFID antenna?

The frequency range of an RFID antenna depends on the specific RFID system and application it is designed for. RFID technology operates across various frequency bands, including low frequency (LF), high frequency (HF), and ultra-high frequency (UHF). LF antennas typically operate within the range of 125 kHz to 134 kHz, while HF RFID antennas operate around 13.56 MHz. UHF RFID antennas cover a broader frequency range, typically from 860 MHz to 960 MHz. Each frequency bands offers different advantages and is suited to different applications. LF RFID systems are commonly used for access control, animal identification, and proximity applications. HF RFID systems are prevalent in applications such as contactless payments, access control, and asset tracking. UHF RFID systems are widely used in supply chain management, inventory tracking, and retail applications due to their longer read ranges and faster data transfer rates.

Why Inlay Innovation/Metalcraft for Custom RFID Antenna Design?

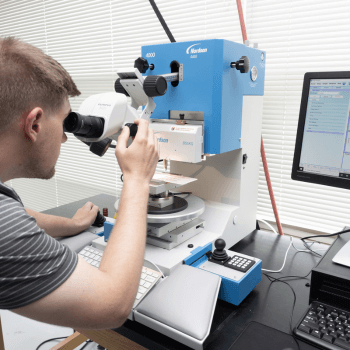

Inlay Innovation, a subsidiary of Metalcraft, Inc. is a custom RFID inlay design and manufacturer. Beyond custom designs, we are committed to being your full-service RFID partner. Our identification experts will help you every step of the way from initial design of your inlay through the manufacturing process. Here's just a few of the reasons Inlay Innovation should be your partner in RFID.

- Quality Driven - Both Inlay Innovation and Metalcraft are ISO certified showing our customers we are committed and comply with with highest manufacturing standards in the industry to ensure our product performs as expected every single time.

- Industry Recognized - We are a Global RAIN RFID inlay manufacturer.

- Scalable Production - No job is too big or too small. We have the production capacity to meet the demand you need.

- Extensive Customization - Regardless if you already have an inlay design or need us to develop a custom inlay design to meet your needs we've got you covered.

- Made in the USA - We offer US-based designs and manufacturing with a sustainable supply chain that will not disrupt you or your customers.

If you have an application for which you need our contract converting and/or inlay design services please contact our RFID Business Development Director, Colynn Black at [email protected].

The only thing “mini” about this tag is its size! With a smaller footprint and lower profile, the Onsite Printable Universal Mini RFID Tag easily fits where other tags may be too large and obtrusive and still gives incredible read ranges compared to other tags in its class.

Want more? More performance, more savings, and more sustainability? Then you want Metalcraft’s new Universal Eco-Mini RFID Tag!

Want more? More performance, more savings, and more sustainability? Then you want Metalcraft’s new Universal Eco-Mini Plus RFID Tag!

From The Asset Tracking Blog

Beyond RFID Tags: Top Questions About RFID Technology

We answer your top questions about RFID technology, including its definition, inventory management and cost.

Demystifying the RFID Inlay Manufacturing Process: From Concept to Card

Want to know how an RFID inlay is created? This article breaks down the process from designing to the finished product.

RFID Dry Inlays vs. Wet Inlays: Choosing the Right Tag for Your Application

RFID inlays come in various types, and this article breaks down how wet and dry inlays are designed for different applications.